BACHLE Metal Drilling Bits

SEND INQUIRY

PRODUCT DESCRIPTION

There are various types of tool bits used for drilling holes in different materials. The most common ones are twist bits, straight bits, and countersink bits. Twist bits create a spiral flute in the material being drilled, which reduces friction and allows for faster drilling. They are commonly used for masonry, metal, and wood. Straight bits, on the other hand, have a flat surface and are used for drilling precise holes in plastic, glass, and ceramics. Countersink bits are designed to fit into the material being drilled and create a perfectly smooth and flush hole.

They are typically used for wood, plastic, and metal. Each type of bit has its own unique features and advantages, making it important to choose the right one for the job at hand.

Bachle drilling bits include for you with the selected 3 types of working conditions:

Bachle wood drilling bits

Bachle metal drilling bits

Bachle masonry drilling bits

Now we are presenting you the specifications of metal drilling bits in hot sales.

Metal Drilling Bits

1. HSS Drill bits

High-speed steel (HSS) drill bits are a type of tool that is used for cutting various types of materials. The manufacturing process of HSS drill bits involves several steps, including:

1.1 Raw material preparation: The first step in the manufacturing process is to prepare the raw material. High-speed steel is typically made from iron and carbon in the form of a billet. The raw material is then melted down and poured into a mold to form the shape of the drill bit.

1.2 Forging: Once the raw material has been prepared, it is placed into a forge to be heated and hammered into shape. This process helps to strengthen the metal and create a sharp edge.

1.3 Grinding: After the drill bit has been forged, it is ground to remove any rough edges and create a smooth, finished surface. This grinding process can be done using different types of grinding wheels, depending on the desired finish and size of the drill bit.

1.4 Quenching: To harden the drill bit further, it is quenched in a furnace at a high temperature. This process makes the drill bit stronger and more durable.

1.5 Tempering: Finally, the drill bit is tempered to improve its strength and toughness. This process involves heating the drill bit slowly and then quickly cooling it to prevent cracking or breaking.

Overall, the manufacturing process of HSS drill bits requires careful attention to detail and skilled craftsmanship to ensure that the final product is high-quality and effective for use in various cutting applications.

We BACHLE brand HSS drill bit offers you different types according to various working situation.

|

Type |

Material |

Processing technology |

Top shape |

Surface finish |

Shank type |

|

HSS Black |

HSS M35 |

Rolling |

Chisel top angel 118° |

Black oxidation |

Straight shank (cylindrical) |

|

HSS White |

HSS M35 |

Full grinding |

Chisel top angel 118° |

Shining |

Straight shank (cylindrical) |

|

HSS Double Ended |

HSS M35 |

Full grinding |

Splint point 135° |

Shining |

Straight shank (cylindrical) |

|

HSS M-Force |

HSS M35 |

Full grinding |

M Type |

Amber colored |

Three flat shank |

|

HSS Titanium |

HSS M35 |

Full grinding |

Splint point 135° |

Titanium coating |

Straight shank (cylindrical) |

|

HSS Co |

HSS M35 contents 5% Co |

Full grinding |

Splint point 135° |

Amber colored |

Straight shank (cylindrical) |

Hereby we offer the BACHLE brand HSS drill bit with mutable shapes, which bearings its own characters during works.

|

Type |

Material |

Top shape |

Surface finish |

Shank type |

Standard |

|

HSS Black |

|

|

|

|

|

|

HSS White |

|

|

|

|

|

|

HSS Double Ended |

|

|

|

|

|

|

HSS M-Force |

|

|

|

|

|

|

HSS Titanium |

|

|

|

|

|

|

HSS Co |

|

|

|

|

|

(TIPS of comparisons)

1. HSS black type is with simple casting rolling process, with an affordable price, effective drilling speed;

2. HSS white type is with better angel & groove;

3. HSS double ended type double the life with two drill bit tips;

4. HSS M-force type provides better speed;

5. HSS tin type with 2.5 times working life;

6. HSS Co type designed for stainless drilling & with longest life.

Hereby we list for you the most common use HSS drill bits in detail size.

|

Part # ( Black) |

Part # (White) |

Part # (Ti +Cobalt) |

Part # (M-Force) |

Diameter (mm) |

Overall Length (mm) |

Working Length (mm) |

|

76401501-B |

76401501-W |

76401501-Co |

76401501-M |

1 |

34 |

12 |

|

76401502-B |

76401502-W |

76401502-Co |

76401502-M |

1.5 |

40 |

18 |

|

76401503-B |

76401503-W |

76401503-Co |

76401503-M |

2 |

49 |

24 |

|

76401504-B |

76401504-W |

76401504-Co |

76401504-M |

2.5 |

57 |

30 |

|

76401505-B |

76401505-W |

76401505-Co |

76401505-M |

3 |

61 |

33 |

|

76401506-B |

76401506-W |

76401506-Co |

76401506-M |

3.5 |

70 |

39 |

|

76401507-B |

76401507-W |

76401507-Co |

76401507-M |

4 |

75 |

43 |

|

76401508-B |

76401508-W |

76401508-Co |

76401508-M |

4.5 |

80 |

47 |

|

76401509-B |

76401509-W |

76401509-Co |

76401509-M |

5 |

86 |

52 |

|

76401510-B |

76401510-W |

76401510-Co |

76401510-M |

5.5 |

93 |

57 |

|

76401511-B |

76401511-W |

76401511-Co |

76401511-M |

6 |

93 |

57 |

|

76401512-B |

76401512-W |

76401512-Co |

76401512-M |

6.5 |

101 |

63 |

|

76401513-B |

76401513-W |

76401513-Co |

76401513-M |

7 |

109 |

69 |

|

76401514-B |

76401514-W |

76401514-Co |

76401514-M |

7.5 |

109 |

69 |

|

76401515-B |

76401515-W |

76401515-Co |

76401515-M |

8 |

117 |

75 |

|

76401516-B |

76401516-W |

76401516-Co |

76401516-M |

8.5 |

117 |

75 |

|

76401517-B |

76401517-W |

76401517-Co |

76401517-M |

9 |

125 |

81 |

|

76401518-B |

76401518-W |

76401518-Co |

76401518-M |

9.5 |

125 |

81 |

|

76401519-B |

76401519-W |

76401519-Co |

76401519-M |

10 |

133 |

87 |

|

76401520-B |

76401520-W |

76401520-Co |

76401520-M |

10.5 |

133 |

87 |

|

76401521-B |

76401521-W |

76401521-Co |

76401521-M |

11 |

142 |

94 |

|

76401522-B |

76401522-W |

76401522-Co |

76401522-M |

11.5 |

142 |

94 |

|

76401523-B |

76401523-W |

76401523-Co |

76401523-M |

12 |

151 |

101 |

|

76401524-B |

76401524-W |

76401524-Co |

76401524-M |

12.5 |

151 |

101 |

|

76401525-B |

76401525-W |

76401525-Co |

76401525-M |

13 |

151 |

101 |

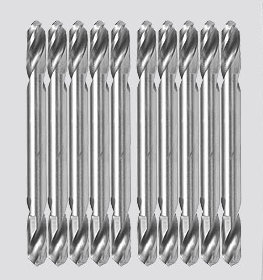

2. Double-ended HSS metal drill bits

Double-ended HSS metal drill bits are a type of drill bit that can be used to make both straight and angled cuts in various materials, such as wood, metal, plastic, and ceramics. The double-ended design allows the drill bit to rotate in either direction, making it more versatile and efficient than single-ended drill bits.

HSS metal drill bits are made from high-speed steel (HSS) and are known for their durability and strength. They are also heat-resistant and can withstand high temperatures without breaking or becoming brittle. Double-ended drill bits come in different sizes and diameters, depending on the specific application and material being cut.

In addition to their versatility, double-ended HSS metal drill bits are also easy to use and maintain. They can be cleaned and sharpened just like single-ended drill bits, and they are less likely to cause damage to the workpiece due to their tapered design. Overall, double-ended HSS metal drill bits are a reliable and cost-effective choice for many DIY and professional projects.

Hereby we present you the list of BACHLE Double-ended HSS metal drill bits for your choice.

|

Part # |

Diameter (mm) |

Overall Length (mm) |

Working Length (mm) |

|

76401601 |

2 |

38 |

7.5 |

|

76401602 |

3 |

46 |

10.6 |

|

76401603 |

3.1 |

49 |

11 |

|

76401604 |

3.2 |

49 |

11 |

|

76401605 |

3.3 |

49 |

11 |

|

76401606 |

3.5 |

52 |

13 |

|

76401607 |

3.8 |

55 |

14 |

|

76401608 |

4 |

55 |

14 |

|

76401609 |

4.1 |

55 |

14 |

|

76401610 |

4.2 |

55 |

14 |

|

76401611 |

4.3 |

55 |

14 |

|

76401612 |

4.5 |

58 |

16 |

|

76401613 |

4.8 |

62 |

17 |

|

76401614 |

4.9 |

62 |

17 |

|

76401615 |

5 |

62 |

17 |

|

76401616 |

5.1 |

62 |

17 |

|

76401617 |

5.2 |

62 |

17 |

|

76401618 |

5.5 |

66 |

19 |

|

76401619 |

6 |

66 |

19 |

|

76401620 |

8 |

79 |

25 |

|

76401621 |

10 |

89 |

25 |

3. Tips for choose metal drilling bits

HSS metal drill bits are a type of drill bit made from high-speed steel (HSS) that is used for cutting various materials such as wood, plastic, and metal. When using HSS metal drill bits, it is important to consider the following factors:

Material being cut: Different materials require different types of drill bits with varying levels of hardness and wear resistance. For example, softwoods may require drill bits with lower hardness, while hardwoods may require higher hardness drill bits.

Drill bit size: The size of the drill bit should be selected based on the material being cut and the desired depth of the cut. Larger drill bits can make deeper cuts but may be more difficult to control.

Speed of the drill: The speed at which the drill bit is rotated should be adjusted according to the material being cut and the desired finish. Higher speeds may result in smoother finishes but may also cause the drill bit to overheat and become damaged.

Drilling conditions: The type of material being drilled, as well as the environment in which it is being drilled, can also affect the choice of drill bit. For example, HSS metal drill bits may not work well in damp or humid conditions.

When selecting HSS metal drill bits, there are several factors to consider:

Hardness: HSS metal drill bits come in different hardness levels, ranging from softer HSS to harder HSS. The appropriate hardness level depends on the material being cut and the desired finish.

Shape: HSS metal drill bits are available in a variety of shapes, including straight bits, spiral bits, and spade bits. The shape of the bit should be chosen based on the specific application and the type of material being cut.

Size: The size of the drill bit should be selected based on the thickness of the material being cut and the desired depth of the cut. Larger drill bits can make deeper cuts but may be more difficult to control.

Brand and quality: It is important to choose high-quality HSS metal drill bits from reputable manufacturers. This will ensure that the drill bits are durable, long-lasting, and produce accurate and consistent results.

English

English