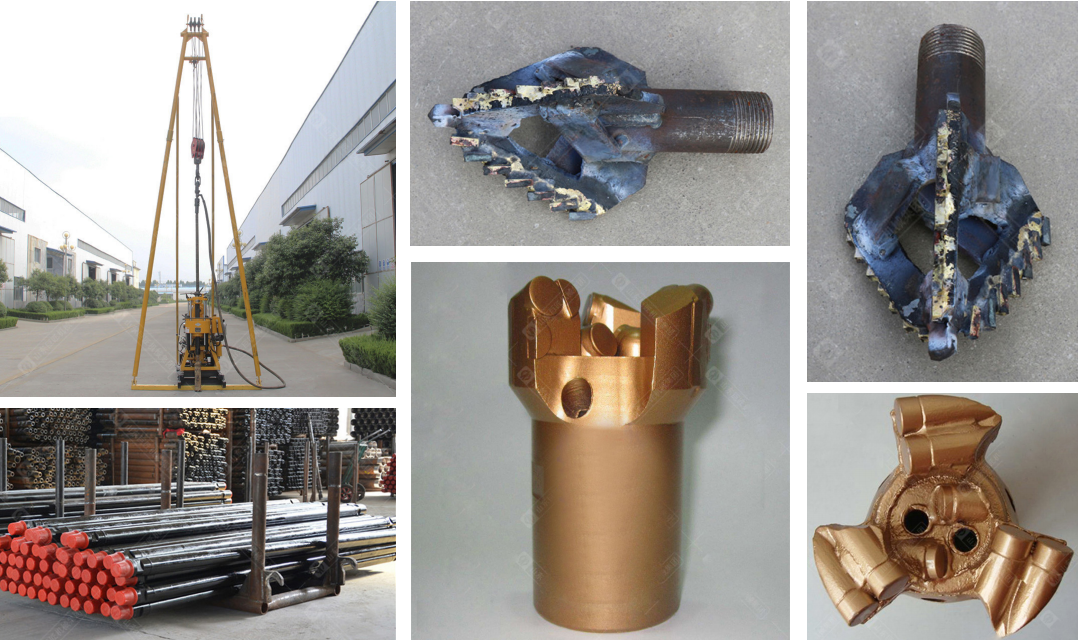

Water Solution: Hydraulic Water Well Drilling Rig

YS-200 HYDRAULIC WATER WELL DRILLING RIG

1. Characteristics of YS-200 wheeled hydraulic water well drilling rig

1) Hydraulic cylinder, high efficiency.

2) Wheeled walking mechanism, very convenient for transport and adjusting the driling rig level.

3) Pressure gauge display the condition of the bottom of the drill hole.

4) The diling rig is equipped with a ball card holding mechanism instead of chuck and it can be operated without stopping the rod.

5) The working efficiency is high and the operation is convenient, safe and reliable.

2. Parameters of Ys-200 wheeled hydraulic water well drilling rig

| Ys-200 wheeled hydraulic water well drilling rig | |

| Drill hole depth | 200m |

| Maximum opening diameter | 300m |

| Final hole diameter | 75mm |

| Drill pipe diameter | 60mm |

| Borehole inclination | 90°-75° |

| Rig weight (without power) | 1300kg |

| Trigonometric belt | B950*4 B1700*3 |

| Active moving distance | 300mm |

| Power | Dieselengine/motor22hp/16.2kw |

| Spindle | |

| Shaft rotation speed | 64/128/287/557 r/min |

| Vertical axis stroke | 450mm |

| Windlass | |

| Maximum lifting weight of single rope | 2400kg |

| Single rope lifting speed | 0.41/0.82/1.64m/s |

| Wre rope diameter | 13mm |

| Wre rope capacity | 35m |

| Hug floodgate caliber | 260mm |

| Hug floodgate belt width | 70mm |

| Mud pump | |

| Type | Horizontal single cylinder double action |

| Diesel engine 17OL/min | Maximum displacement |

| Matching motor 15OL/min | |

| Maximum pressure | 3Mpa |

| Work pressure | 1.5Mpa |

| lnlet pipe caliber | 40mm |

| Outlet pipe caliber | 30mm |

| Triangle conveyer belt | B1728mm |

| Type | CBT—F—314 |

| Triangle conveyer belt | B1100*1 |

YS-300 wheeled hydraulic water well drilling rig

1. Characteristics of YS-300 wheeled hydraulic water well drilling rig

1) The driling rig is equipped with wheeled walking mechanism and hydraulic cylinder support, which is convenient for the whole machine to be relocated and easy to adjust the level of the drilling rig.

2) Usng the ball card holding mechanism to replace chuck,can implement non-stop down rod,convenient operation,safe and reliable.

3) With oil pressure feeding mechanism to improve drilling efficiency.

4) The pressure gauge is provided with the pressure gauge of the bottom of the hole, so it is easy to master the hole in the hole.

5) The lifting and falling tower is hydraulic operation, which is convenient and reliable.

6) The diesel engine uses electric start to reduce the labor intensity of the worker.

2. Parameters of YS-300 wheeled hydraulic water well drilling rig

| YS-300 wheeled hydraulic water well drilling rig | |

| Drill hole depth | 100/250/300/600m |

| Maximum opening diameter | 300/200/150/75mm |

| Max open hole caliber | 300mm |

| Final hole diameter | 75mm |

| Drill pipe | 60mm |

| Borehole inclination | 90°-65° |

| Spindle | |

| Rotation speed | 30-1050r/min |

| Reversal speed | 29-137r/min |

| Vertical axis stroke | 560mm |

| Diameter of shaft inner hole | 96mm |

| Vertical axis lifting capacity | 60kn |

| Main hoist | |

| Single rope lifting speed | 0-45m/min |

| Mire rope diameter | 14mm |

| Band width | 90mm |

| Drum diameter | 300m |

| Reel capacity | 30m |

| Maximum lifting capacity of single rope | 40kn |

| Auxilliary hoist | |

| Type | Horizontal single cylinder double action |

| Drum diameter | 140mm |

| Diameter of steel wire |

6mm |

| Reel capacity | 450m |

| Mud pump | |

| Mud pump | Bw-250 Horizontal three cylinder |

| Flow | 250l/min |

| Working pressure | 7mpa |

| lnlet diameter | 75mm |

| Outlet diameter | 50mm |

| Gear oil pump |

|

| Double oil pump |

CBF-F63/25 |

| Front-end flow pressure |

63 l/min 20mpa |

| Backend flow pressure |

25 l/min 20mpa |

| Rig power |

|

| Diesel engine |

FAW Xichai 4 cylinder |

| Electric machinery |

Y180L-4 22KW |

| Wheeled chassis |

|

| Bearing capacity of wheel chassis |

3.5t |

| Wheel chassis length |

2.6m |

| Wheel chassis width |

2m |

| Wheel chassis height |

0.6m |

Precautions during drilling

1) Drilling rig support:

The drilling rig adopts a triangular bracket to ensure its firmness and reliability.

Construction personnel should regularly inspect the supporting parts and promptly identify hidden dangers.

2) Safety warning signs:

lnareas prone to injury or danger, clear safety warning signs should be set up according to national standards.

3) On site fence:

The site should adopt a closed enclosure structure with a height of no less than 1.8 meters.

4) Appearance field

The site should be flat and the roads shall be unobstructed;

5) On site fire prevention:

The fire protection equipment shall be configured correctly and should meet the fire protection requirements.

English

English